By Brian Wallace

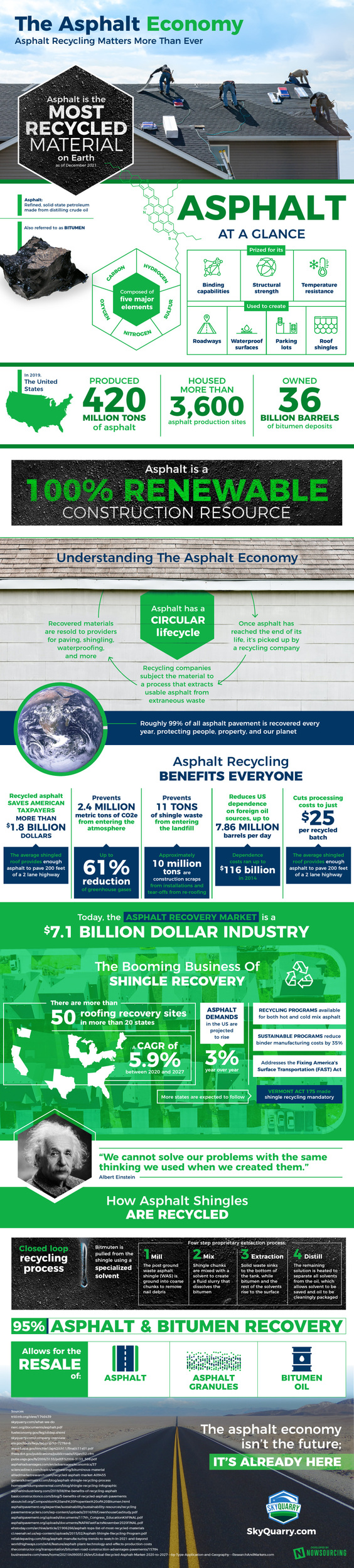

The asphalt economy is incredibly fascinating and sustainable. As of December 2021, asphalt is the most recycled material on Earth and can be used for roadways, parking lots, roof shingles, and more. With the current state of climate change and efforts to become more sustainable, asphalt recycling matters now more than ever. The United States is already heavily involved in the asphalt industry. In 2019, the U.S. produced 420 million tons of asphalt, housed more than 3,600 asphalt production sites, and owned 36 billion barrels of bitumen deposits.

What is asphalt? Asphalt, which is also referred to as bitumen, is a refined, solid-state petroleum made from distilling crude oil. Asphalt is a 100% renewable construction resource. Composed of five major elements, carbon, hydrogen, oxygen, nitrogen, and sulfur, asphalt is prized for its binding capabilities, structural strength, and temperature resistance. It is used to create many different types of surfaces; namely, roadways, waterproof surfaces, parking lots, and roof shingles.

Understanding the sustainability of the asphalt economy is important. Asphalt has a circular lifestyle, meaning it has a sustainable life process. Roughly 99% of all asphalt pavement is recovered every year, protecting people, property, and our planet. Recycling companies subject the material to a process that extracts usable asphalt from extraneous waste, then recovered materials are resold to providers for paving, shingling, waterproofing, and more. Finally, once the asphalt has reached the end of its life it’s picked up by a recycling company, and the entire process is repeated.

Asphalt Recycling benefits everyone. The asphalt recycling industry has both environmental and financial benefits. In terms of the environment, asphalt recycling prevents 2.4 metric tons of CO2e from entering the atmosphere, which is up to a 61% reduction in greenhouse gasses. It also prevents 11 tons of shingle waste from entering the landfill. The financial impacts are both country-wide and individual. Recycled asphalt saves American taxpayers more than $1.8 billion. Additionally, asphalt recycling reduces the United States’ dependence on foreign oil sources by up to 7.86 million barrels per day.

Today, the asphalt recovery market is a $7.1 billion industry. Shingle recovery has become a booming business; currently, there are more than 50 roofing recovery sites in more than 20 states. Asphalt shingles are recycled in a closed loop recycling process. Bitumen is pulled from the shingle using a specialized solvent. First, the asphalt is ground into chunks to remove nail debris, then single chinks are mixed with the special solvent to dissolve the bitumen. During this process, the solid waste sinks to the bottom of the tank while the bitumen and rest of the solvents rise to the surface. The remaining solution is heated to separate the solvents from the bitumen oil, which is then packaged.

Demands for asphalt have been increasing, and the asphalt recycling industry has modified to adapt to this new demand. Asphalt demands in the United States are projected to rise 3% year over year. Recycling programs are now available for both hot and cold mix asphalt. These sustainable programs reduce binder manufacturing costs by 35%. 95% of the asphalt and bitumen recovery allows for the resale of asphalt, asphalt granules, and bitumen oil. The asphalt economy isn’t the future; it’s already here.

Source: InvestSkyQuarry.com

Source: InvestSkyQuarry.com

Brian Wallace is the founder and president of NowSourcing, a infographic design agency based in Louisville, Ky., and Cincinnati, Ohio, and works with companies that range from small business to Fortune 500. Wallace also runs a local event to make the Louisville/Cincinnati region more competitive (#thinkbig).

Brian Wallace is the founder and president of NowSourcing, a infographic design agency based in Louisville, Ky., and Cincinnati, Ohio, and works with companies that range from small business to Fortune 500. Wallace also runs a local event to make the Louisville/Cincinnati region more competitive (#thinkbig).